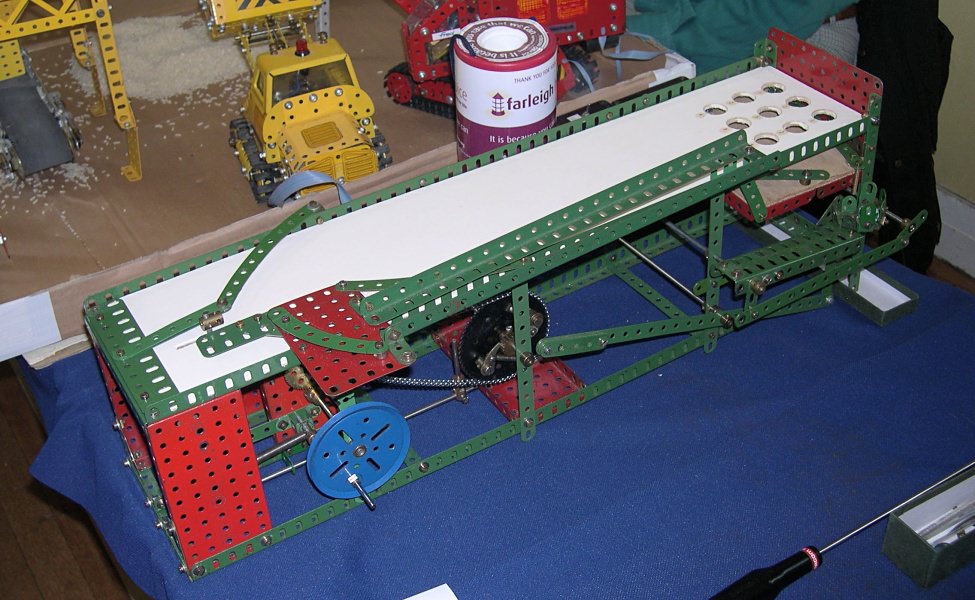

Meccano Bagatelle Table Rebuild

Written by Keith Patey for our January 2008 Newsletter

This model is № 9 of Geoff Wright’s Meccano Super Models.

With no marbles to hand (rumour has it that I lost mine years ago!) the first step was to locate some of those small round objects of which I had many when I was a lad (very good memory and imagination, you may surmise!). I drew blanks (also incredulous stares) from assistants in local toy shops who seemed to treat my request with good humour but produced no round objects. The grandchildren will let me have some of theirs, surely. They were having none of it, however, and defended their stock of ‘Kerplunk’ ammunition with surprising tenacity. My pleas proved less than persuasive and no amount of bribery or subterfuge yielded anything. A saviour was close at hand in the shape of the Wife’s sewing-box. She discovered two of these priceless objects among the paraphernalia contained therein.

Bagatelle table

All was now ready for building. The departures from the original were as follows:

- The length was extended to 24½”. This obviated the necessity to join girders thus giving a neater appearance.

- 5½” x 2½” flanged plates were used in place of 5½” strips to re-enforce the lower corners.

- A 3½” pulley, with threaded pin, replaced the two-crank combination handle from which power can be derived.

- Reduction gearing was mounted within the framework (not outside) and utilised one of Nick Rudoe’s ¼" face, 57-tooth gear wheels.

- The 2” sprocket wheel was replaced with the 3” version, which was fitted with a free-wheel device. This meant that the mechanism could only be activated by turning the handle clockwise. Rotation in the opposite direction had a tendency to snag the horizontal rods by pulling, rather than pushing, against the vertical rod in the firing sequence. Over-enthusiastic operation, under this method, could place undue strain on the small sprocket wheel with the possibility of loosening its boss.

- A bracing 5½” x 2½” flanged plate has been located at approximately midway along the base and also provided a bearing for the 11½” rod of the firing mechanism. In the original, this rod did not have a bearing at its far end which could have resulted in undue pressure on the “floating” rod causing it to distort slightly.

- Four 6½” strips served to join and brace the top and bottom girders.

- 7½” girders replace the 5½” version in the original making the two flat trunnions redundant.

- The collecting plate, beneath the large holes has been re-enforced with a small piece of plywood. The smaller marbles had a tendency to “stick” in the holes of the 5½” x 2½” flanged plates without this. A girder and perforated strips have been used as a substitute for one of the large curved strips.

- The table is a piece of hardwood, cut to size and painted with some old stock (from an old D. I. Y. remnant) found in out-of-the-way cupboard, and drilled with nine holes replacing the six in the original. The holes were then given a score-value with some small Letraset transfers and coated with varnish.

- Slight modifications were required to feed the small marble towards the smaller firing pin.

There is no real skill involved in operating this game as the firing mechanism is rather set in its ways. There does, nevertheless, seem to be some play-value, if the level of interest shown by the visitors to the exhibition on 13th October 2007 is anything to go by.

Watch our video of this model