Consider Your Bearings

Written by George Foard for our March 2009 Newsletter

Throughout the history of Meccano we have seen axle rods journalled in one thickness of plate, strip or whatever. This is OK when there is no immediate load, through either a unit rotating around an axle or a driven axle supported in some way by a framework — providing the action is intermittent, as in the greater part of models illustrated in the manuals.

But above these factors we head for trouble, as, for example, round holes become oval and/or axle rods develop concentric grooves. A terrible waste of expensive parts. There are ways and means of avoiding this damage.

The following suggestions are not necessarily mine I’m sure, and have been aired many times by builders, but there is no harm in repetition.

- Bolting bossed parts, i.e. a bush wheel, to a framework to support an axle.

- The common fishplate used in multiple; two, six or even ten, bolted through their slotted holes to a frame.

- As in 2, but using flat trunnions, for example.

These ideas are only three methods and will be dictated by space available. In the ‘new wave’ of Meccano parts there is a part (in plastic) no. A420/0260C, which is 1½” long (three holes in line) spacer-type, with a bearing surface of about ¼”. It’s ideal.

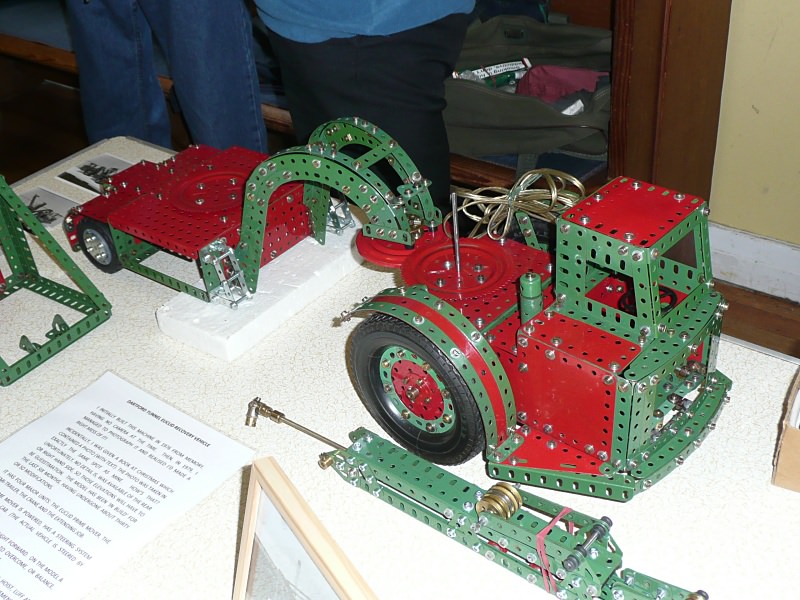

George’s model of the Dartford Tunnel Euclid Heavy Recovery Vehicle uses various bearings as described in this article

There are three other important factors to ensure smooth, lengthy running.

Firstly, sort out your axles: they must be straight. This is well nigh impossible, as we are led to believe that in the early days the Meccano factory received its steel stock for axles etc in coils from the suppliers. The ‘new wave’ bright round axles are much better. The triangular section axles are OK: again, if well supported.

Secondly, how about alignment? Check this using a known straight rod or a drift. After tightening-up, check again. A drift is a ‘must have’ in your tool kit.

Thirdly, lubrication. I personally do not use the thin ‘Three-in-One’ or ‘Everyman’ type oils. I find it gets thrown everywhere except where it should be, and seems to evaporate in time. I use an automobile lubricant at all times. In fact, model railway rolling stock I last oiled 30 or 40 years ago is still ‘well oiled’! There are other satisfactorily-proved lubricants I’m sure. Be careful, though, when oiling gearing.

Try and avoid some greases as they tend to harden as per some small mechanical items shipped out from the East. You will then have the job of removing it.

Remember: If alignment or spacing is doubtful you may end up inadvertently manufacturing your own brand of grinding paste!