Dear Cathy

Written by Cathy Warrell for our September 2012 Newsletter

John Gay has been inspired by my article on Meccano Repairs in the March 2012 newsletter and sent me this letter about his own experience:

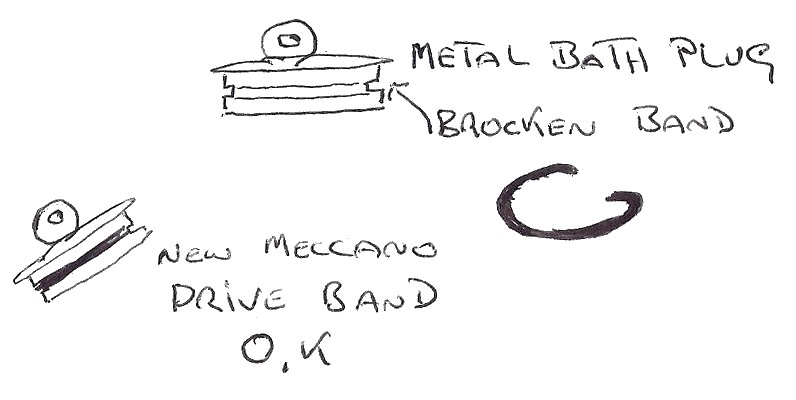

“Just this week the rubber seal on the metal bath plug perished, so the bath water was running away. So it was Meccano to the rescue — the old perished rubber seal was replaced by a Meccano drive band (part № 186) and it works well.”

John’s seal solution

Thanks for your letter, John. It sounds great! I didn’t know you could get metal bath plugs — ours are all rubber! Actually, I’m not the best person to be talking about Meccano at all, since I find it very hard to bolt any of it together at all. The last time I tried I felt I could do with at least two extra hands! I think I’ll hand my Meccano Repairs column over to Chris and have a Cathy’s Cakes column instead!

Les Chatfield has also been keen to share with us his experience with Meccano repairs:

“I made a ‘repair’ to a (non Meccano) model of Hastings East Hill lift. The original drive was home made and I replaced it with this gearbox assembly that utilises plastic gears as silent running was essential.

Les’s gearbox

Of interest is the long bolt fitted through a hole in the plastic gear wheel driven by the non-Meccano motor. The drive to this motor was reversed by the cars of the model hill lift itself operating limit switches wired through to a clever DPDT relay made from an old H & M point motor.

The long bolt driven by the gear wheel has to rotate a complete revolution before encountering another long bolt securing the small plastic pinion to the shaft. Both gearwheel and shaft would then revolve together driving the rest of the gear train and the winch operating the hill lift.

This simple device gave the cars a brief ‘wait’ at each and of their journeys before starting off again.

The Hill lift model itself may be seen at the Brighton Toy and Model Museum (where I used to work as ‘Train Doctor’).”