Hints & Tips № 5 — Centering a 4x4 Module on Meccano Plates

Written by Frank Paine for our February 1996 Newsletter

No, this isn’t about axle stands for your Range Rover.

The Meccano braced girder, almost uniquely in the system, is four holes wide. It is, of course, ideally suited to the construction of small-scale lattice booms and towers, which is why it was introduced, in about 1916.

A model I made, a little while ago, reproduced a lighting tower erected in my home town for an exhibition, and made good use of braced girders. The full-size tower was actually a tower crane without a jib, with various lights and fandangles fixed to it. My model consisted essentially of braced girders joined by angle girders at each corner, forming a 4x4 hole square section lattice tower.

The base construction was interesting, trying to reproduce the original, and the point of attachment for the tower was a 5x7 hole flanged plate. Problem.

All Meccano plates, with few exceptions, are an odd number of holes long and wide, which means they have a central hole. A 4x4 hole module does not. Whichever way I fitted angle brackets to the bottom of the tower, their holes would not line up with those on the base, with the tower central.

Solution — a ‘transfer plate’. This is a device used in structures between elements to be joined that have incompatible connection arrangements.

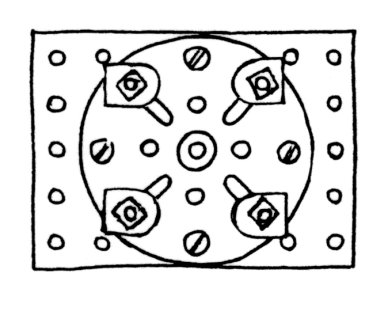

A Meccano face plate has radial slots. I realised that if one were placed at the bottom of the tower, so that the slots were on the diagonals of the 4x4 square, these could be used to connect it to the tower, via the angle brackets. Full use of the tolerance provided by the slotted holes in the angle brackets and angle girders would be required, but they could be lined up.

Centering a 4x4 module on Meccano plates

The round holes in the face plate could then be used to fix down to the base. The face plate would not lay flush against the base plate, because of the heads of the bolts fixing it to the tower, so spacing washers under it at the bolts to the base plate would be needed to avoid excessive flexing.

Of course there are other Meccano parts with diagonal slots that may be used in a similar way — 3” pulleys, circular plates, ball races and, of course, the geared roller bearing! These are all stiffer than the face plate so should be more rigid. 4x4 is not the only even numbered module that can be connected, of course. 6x6, 8x8 etc. are possible. But, I wonder, what about rectangular tower sections?