Hints & Tips № 6 — Polishing Aeroplane Constructor Bolts

Written by Frank Paine for our May 1996 Newsletter

Now, I wouldn’t want those of you without the good fortune to own a Meccano Aeroplane to think that I’m trying to make you envious. I am, of course — I just don’t want you to think so.

Not even when I tell you that the first two Constructor Aeroplanes I obtained were found, dismantled but virtually complete, at the bottom of a box of miscellaneous Meccano I picked up for seven quid. I hadn’t even realised they were there.

Enough of this odious one-upmanship. Imagine the scenario. Small boy opens Christmas present. Great delight as he assembles the aeroplane to the latest, up to the minute design of biplane, securely bolted together and looking magnificent. Boy does not see prominent notice on box ‘Do Not Try To Fly This Aeroplane’, because there isn’t one.

Boy looks at his treasured possession. It looks just right. Feels quite light. Surely it’ll fly. I really must try. Up to the bedroom window… which is where the poetry ceases.

The disappointment of his creation having all the flying characteristics of a brick, and its slightly mangled state as a result of his finding out, must have resulted, in many cases, in the toy being eventually consigned to the back of the toy cupboard, or even the loft, with its damp and dusty dangers.

There was not, after all, a great deal of ‘play value’ in the Meccano Aeroplane, even if there is now a very strong nostalgia and rarity appeal. (What’s all this got to do with polishing? — Editor)

So the condition of these interesting oddities often leaves much to be desired — especially the bolts. These are generally dome-headed, sometimes unaccountably called taper-headed, and chromium (or is it cadmium?) plated. These look superb when shiny, but how to clean them when they’re not? (Ah, here we are!)

With mine, I thought gripping the thread hard and rubbing vigorously against a cloth with a little chrome cleaner on it was a good idea, but my wife said it ruined her nails, and couldn’t I do it myself instead?

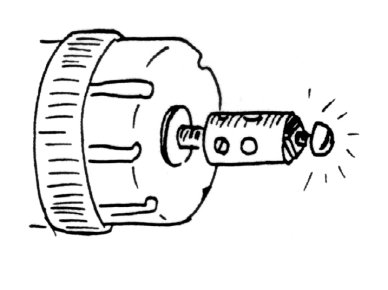

I had to agree, but mechanised the operation. I fitted a threaded coupling onto the spindle of an electric motor (a PDU bolted to a baseplate), and inserted the bolt to be polished into the threaded end, with a nut halfway down the thread. Hand-tightening the nut against the coupling was enough to hold the bolt firmly, so it could be rotated at speed against the cloth with a little Solvol Autosol on it.

Polishing Aeroplane Constructor bolts

The results were brilliant — literally. Even apparently heavily rusted bolt heads came up shiny, needing only the fluff to be removed from the slots.

I’m sure those shiny bolt heads are an improvement, aerodynamically speaking — less drag, greater lift. etc. Hang on a minute, I’m just popping up to the bedroom window to try something out.

A final thought. What about the nuts? That’s a tough one to crack.