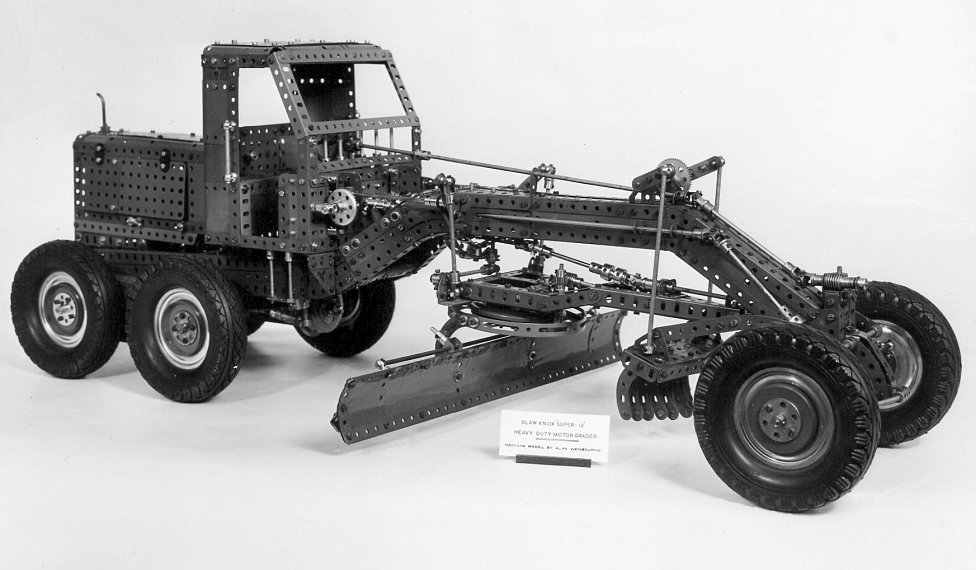

Blaw Knox ‘Super 12’ Motor Grader

Written by Alan Wenbourne in April 2024

The following article appeared in the July 1960 issue of Meccano Magazine.

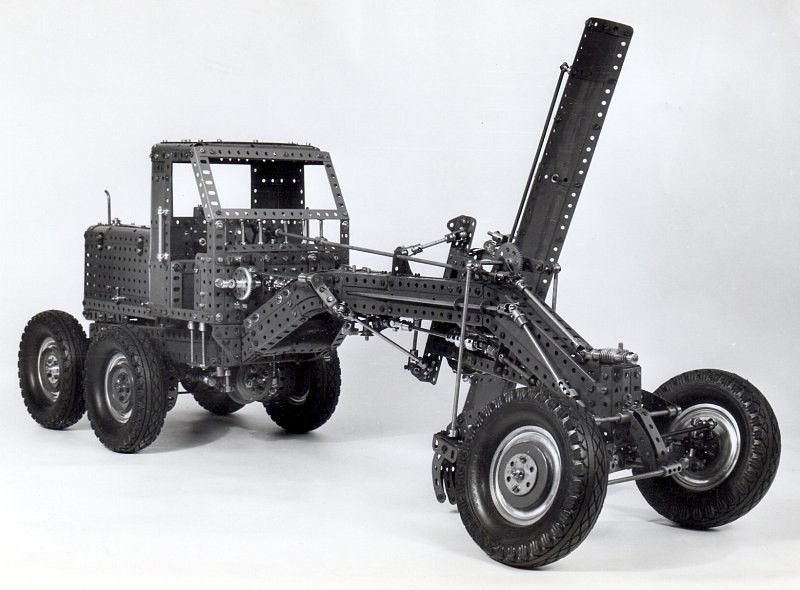

General view

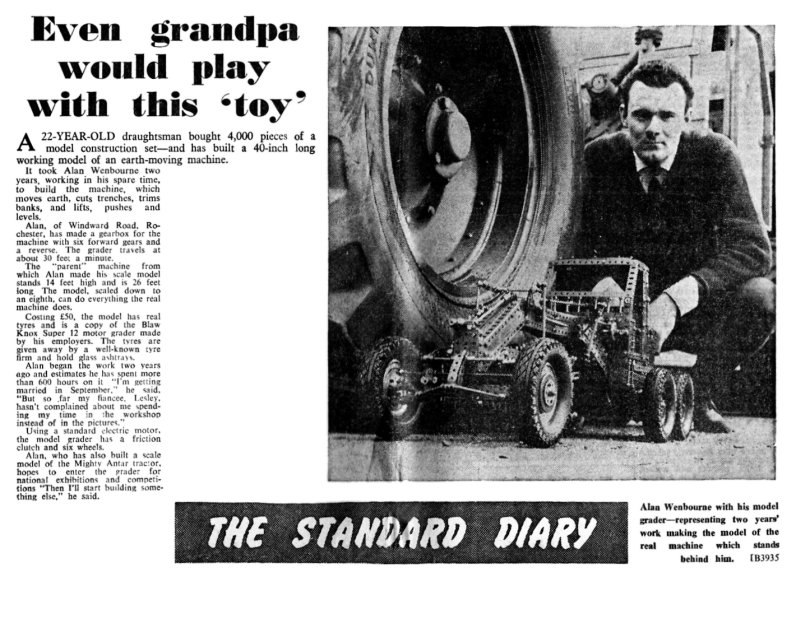

One of the most attractive, complete and finely-proportioned models that has come to our notice in recent years is a highly-detailed version of the well-known Blaw Knox ‘Super 12’ Motor Grader. It was built by Mr. Alan Wenbourne of Rochester, Kent, and is shown in the illustration to this article. Mr. Wenbourne, who recently completed his apprenticeship at the Rochester Works of Blaw Knox Limited, began to build the model early in 1958. He is an expert Meccano constructor, as this splendid model testifies, and he has been interested in the hobby since he was eight. Before describing the main features of this attractive model, we think that readers will be interested in the following details of the actual Blaw Knox ‘Super 12’.

Although called the ‘Super 12’ Motor Grader, road grading is only one of the many functions of this machine. By adjusting the grading blade it is possible to change from repairing and making roads, where the blade is underneath the Grader, to bank cutting and shoulder trimming, for which purposes it is adjusted at the required angle at the side of the machine. The adjustment of the blade for these various operations can be carried out by the operator in a few seconds, without moving from his cab. It is simply a matter of manipulating mechanical power controls placed within easy reach.

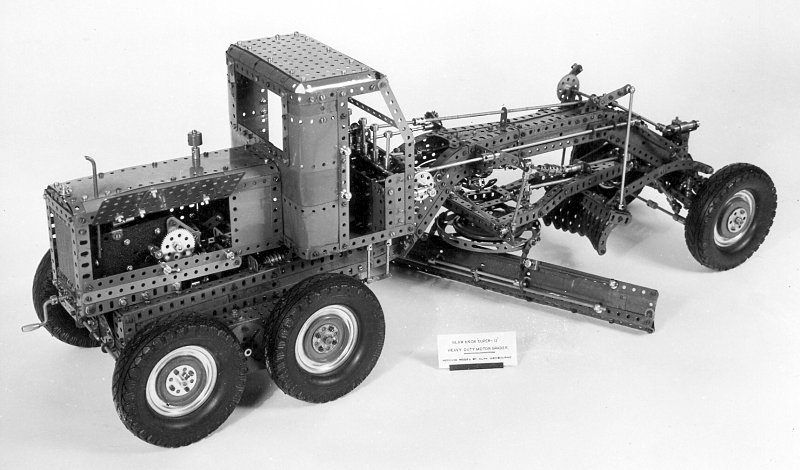

Rear view

The Grader can also be fitted with a Scarifier, a kind of multi-toothed rake, which is used for ripping up worn road surfaces. The Scarifier is extremely robust, and its large steel teeth, or ‘tines’ as they are called, are made from tough manganese steel and are readily replaceable.

It is quite a sight to see the ‘Super 12’ in action breaking up a hard well-worn macadam road with its eleven steel tines, ripping into the surface to a depth of over one foot.

The Grader can also be fitted with a snow plough. When equipped in this way it is capable of clearing a nine foot wide lane in one pass through the heaviest falls.

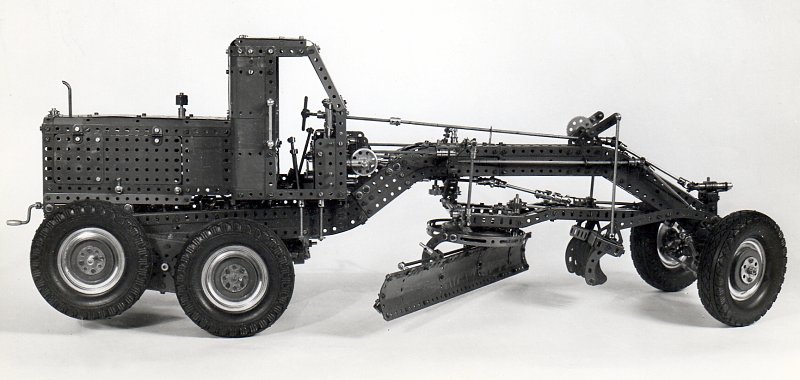

Side view showing the articulation of the rear tandem driving wheels

In fact, it is almost impossible to list all the functions for which a Blaw Knox ‘Super 12’ is adaptable, and the power to carry out these different tasks is derived from a Leyland 6-cylinder diesel engine that develops 118 hp at 1,650 rpm. It drives through a gearbox giving six forward speeds ranging from 2.31 mph to 19.70 mph, and two reverse speeds of 3.08 mph and 4.90 mph.

Among other features of the ‘Super 12’ are four-wheel tandem drive and leaning front wheels to counteract side draft and ensure a straight course.

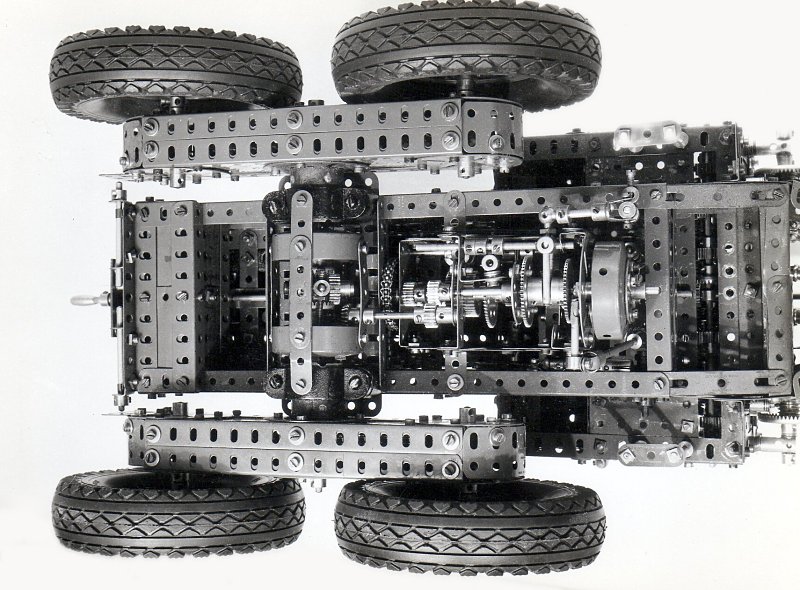

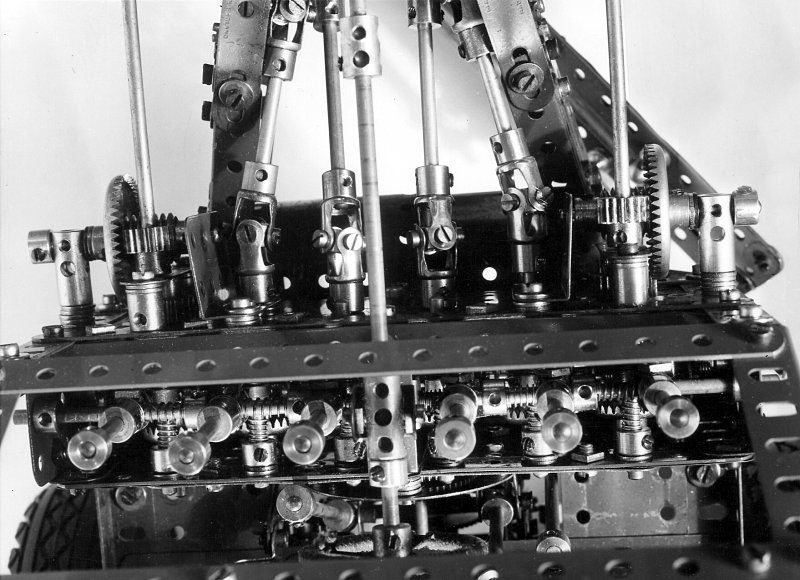

Underside view showing the main gearbox and transmission to the four-wheel tandem drive

In building his Meccano model of this Grader, Mr. Wenbourne has tried to reproduce the identical features of his prototype as accurately and completely as possible, and his efforts, combined with a high degree of skill in the use of Meccano parts, has resulted in the really splendid workmanship seen in the illustrations.

The model is powered by a Meccano E20R Electric Motor, which transmits through 90:1 reduction gearing, to a heavy-duty friction-type clutch operated by a foot pedal in the cab. Power is then transmitted to a six forward speed and two reverse speed gearbox, which incorporates an internal expanding transmission brake. The gear ratios are forward, 1:1, 2:1, 3:1, 4:1, 6:1 and 9:1. The reverse ratios are 6:1 and 9:1.

The final drive consists of a differential situated in the semi-floating rear axle, half shafts of which are connected to tandem drive boxes on each side. These house chain drives to the rear wheels.

Here the blade is angled at 90° and the front wheels leaned at 25°

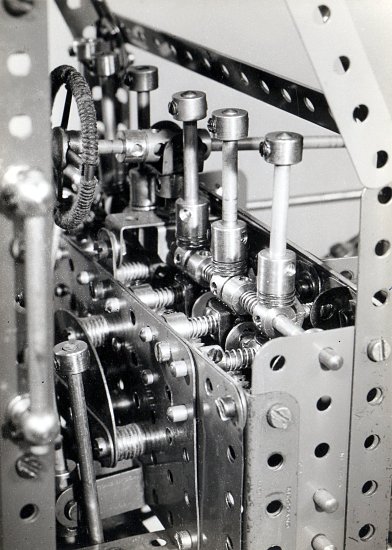

Power is taken from the gearbox to a power control box mounted on the dashboard. This gearbox consists of six reversing mechanisms, each with a neutral position, which are engaged or disengaged independently by six levers situated three each side of the steering wheel. These six drives control blade lift, left- and right-hand side shift, circle, scarifier and wheel leaning. The blade is supported on a tilting frame, which is universally jointed at its front end.

As well as being capable of mechanical side-shift, the blade can be moved sideways manually in the tilting frame, a combination of both giving maximum side reach. The blade can be revolved through 360° and by altering the length of the lift arms can be driven into the vertical position. The front wheels can be leaned to give additional steering lock, or to counteract side-thrust when grading, just as in the real machine.

Provision is made for four-wheel operation by a locking device which acts on the tandem drive boxes, and enables either the forward or aft pair of rear wheels to be held clear of the ground.

Drives

Other features of this very fine model are a pivoting front axle, Ackermann steering, adjustable blade pitch angle and a toolbox at the rear of the frame.

The model is built to a scale of 1½”:1’ and has an overall length of 3’ 3”, with a total weight of 30 pounds.

Close-up view looking into the cab at the power control gearbox

We extend our congratulations to Mr. Wenbourne on his very fine achievement.

Cutting from the Chatham Standard, 23rd August 1960